From the Field to the Table

Choosing the right time to harvest popcorn is tricky. It is best to delay harvesting until the corn has cured on the stalk as much as possible, but not so long that it is damaged by fall moisture or by corn stalks falling over. For decades, popcorn has been picked almost exclusively by machines.

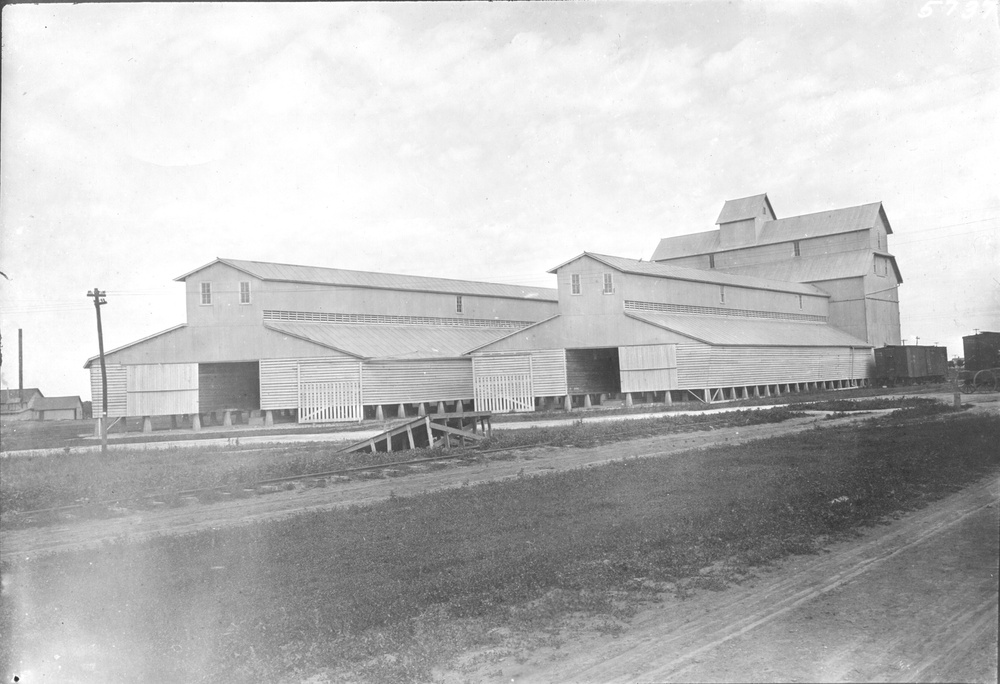

Once picked, the corn must be dried until it reaches its optimum moisture level of 13.5% to 14%. Proper air circulation in the crib is essential for drying and for prevention of mold and other harmful pests. Through the years, there have been many variations on storing and drying popcorn for future use, from natural air drying to artificial drying with heat, and large-scale crib drying by commercial processors to small-scale drying in wire cloth bags by families for home use.

After the corn has been dried, it is transported to a processing plant where the kernels are shelled from the cob and move through several screens and separators to remove any damaged kernels or debris. Then the kernels are sent through polishing machines to rub off any chaff that may still be clinging to them. After processing, popcorn is packaged in containers. For wholesale use, the kernels are packaged in large bags of 25-, 50-, or 100-pound sizes. Meanwhile, for retail sale, smaller jars, bags or metal containers are used. Microwave popcorn has led to the creation of even more types of packaging.

An official website of the United States government.

An official website of the United States government.